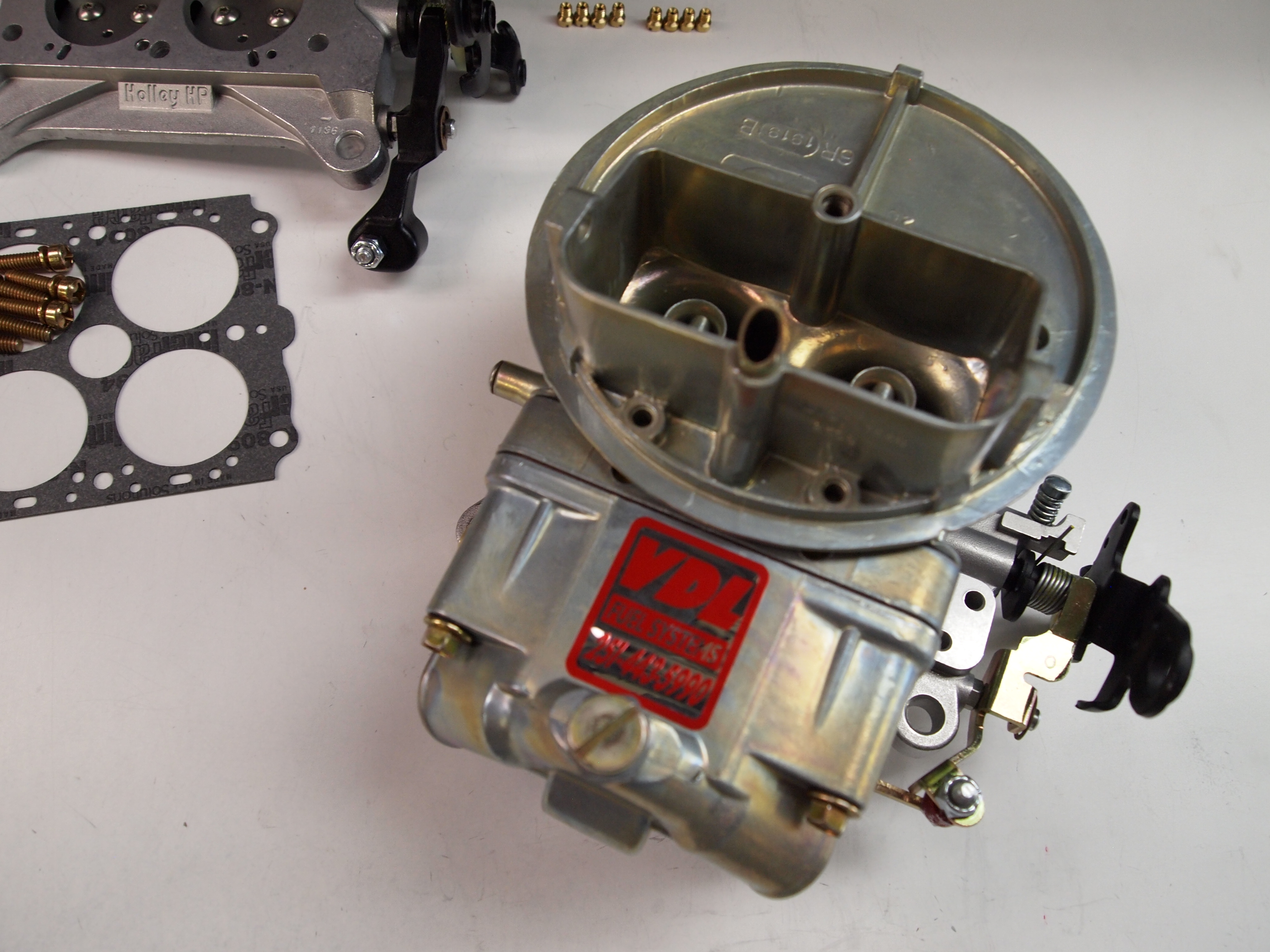

This carburetor has been the sanctioning bodies’ answer to slowing cars down and creating an equal playing field. Well, they got it half right. The power is significantly reduced by the restricted airflow; but the performance difference between an “out of the box” carburetor and one that has been properly modified eliminates the equal playing field.

Whenever a carburetor is sized improperly to the engine like this one is, there are a variety of problems that arise. The air/fuel circuitry was designed for a low air speed/horsepower application. When this design is applied to a high air speed situation, it produces a rich, poorly emulsified fuel mixture. VDL Fuel Systems has done extensive dyno and track testing to recalibrate the air/fuel circuitry, accelerator pump circuit, and idle circuit to produce optimum torque, horsepower, and drivability.

Airflow is of the essence with a restricted carburetor. VDL Fuel Systems takes every part of this carburetor and maximizes the potential airflow while still operating within the tech parameters. After the main body, boosters, base plate, and throttle are machined to the minimum/maximum sizing, they are vibratory polished and recoated.

Assembly is done to tolerances unobtainable in high volume production. Boosters are installed within .001’’ on height, twist, and pitch. The base plate is matched to the main body. All gaskets are properly matched to the main body to prevent overhang. And finally, the throttle plates are adjusted for optimum position angle on the flow bench. VDL Fuel Systems produces a custom-built, fully optimized carburetor built to your specifications and engine application – not just another “out of the box” carburetor.

Application – IMCA / Street Stock / 4 cylinder $850

- Custom built to each unique set of track rules across the country

- Venturis blueprinted to maximum sizing

- Air/fuel circuitry calibrated

- Idle circuit calibrated

- Accelerator pump circuit tailored to application

- Welded throttle shaft

- Base plate matched to main body

- Boosters calibrated, sized, and precision installed

- All parts vibratory polished for enhanced airflow

- Also available in cast aluminum

Tuning Tips for your Holley 7448

A 350 cfm carburetor used in a racing application presents some unique tuning challenges because of the very small venturi size vs. the airflow pulled through them because of the high horsepower engine. The following are some tips on tuning and maintaining your carburetor that we have learned over the years through dealing with hundreds of different applications and drivers:

Float Level – The fuel level in the bowl should be set about 1/8″-3/16″ below the sight hole so that you have to jostle the car heavily to get the fuel to come out the sight hole when running. We set the float in the shop to a particular setting; but fuel pressure dictates fuel level. Therefore you must set this when you first install the carburetor. If the float is set too high the carburetor will be too rich at low rpm and/or part throttle conditions. You will particularly notice this when coming off the corners. It should be noted that at a no-load situation, such as in the pits setting the timing, the carburetor will always have a slight rich condition at probably 3000 rpm. This is due to the fact that the strong booster signal and the fuel metering that enables us to make good torque numbers is pulling a lot of fuel in at this rpm/vacuum. At the same time there is no way to burn the fuel because there is no load, and the engine will flutter. Finally, after setting the float, always give the carburetor time to burn off enough fuel to reopen the needle/seat so that your new setting is really what you are seeing. Many times people lower the float too much because they haven’t waited a sufficient amount of time for the fuel to burn off and the new setting to take.

Throttle Blade Adjustment – The throttle blade should be set at an rpm that is as low as possible to keep from pulling through the high speed circuit/the boosters at idle. If you should lose your setting just back it completely off, put 1 round in, and start there.

Idle Mixture Screws – Always adjust the 2 idle mixture screws evenly. The settings on both should be the same. Our original setting is 2 turns out. If for some reason your engine absolutely needs a different setting on one side you can just about bet something is wrong with the engine causing it to have a different signal/vacuum on that side.

Fuel Pressure – 6 to 7 pounds. You should absolutely know what your fuel pressure is! Many racers have no clue what their fuel pressure is, and they chase engine problems for weeks when a simple fuel pressure gauge would have indicated the problem straight away.

Vent Tube Clearance – You must have at least ¾” clearance above the vent tubes. It is ok to lower the vent tubes if absolutely necessary, but you will begin to run the risk of fuel spilling over in the turns if you are not careful.

Pump Circuit Tuning – Because of the differences in track conditions and driving styles you may need to adjust the pump circuit, i.e. pump cam/pump arm, to correct “off corner” stumbling issues. If an engine stumbles two or three times after the driver steps into the throttle this usually indicates too much fuel and can be corrected by adjusting slack in the pump arm or installing a smaller pump cam. If an engine has a “dead hesitation” and then picks right up and goes, this usually indicates not enough fuel on the pump circuit. First confirm that the pump arm has no slack in the adjustment then proceed to increase pump shot with either a larger pump cam or a larger pump nozzle.