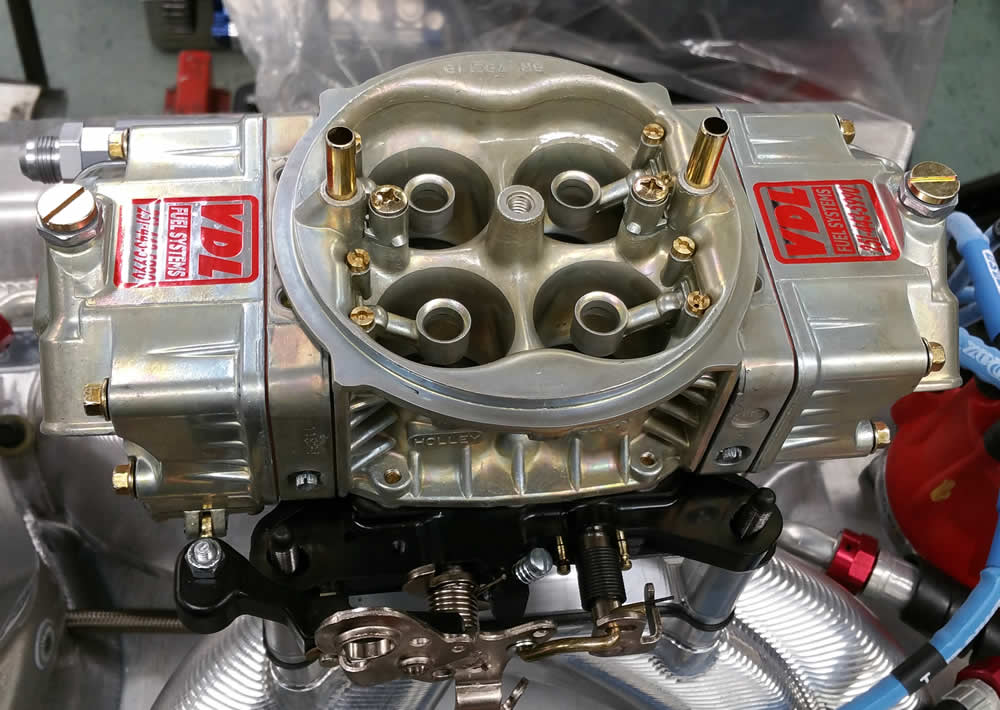

CUSTOM CNC BIG BORE CARBURETORS

These carburetors are built for the high power small block engines up to the big block racing engines. Very capable of sufficiently feeding an engine up to 950 horsepower on gas, these carburetors are sized to each application so that each carburetor flows enough air to make all the top end horsepower possible while keeping the venturi size small enough to maintain good air speed at the lower rpms to provide great restarts and low end response. Many racers have found on their big block applications that taking a Dominator carburetor off and installing a VDL Fuel Systems custom CNC carburetor resulted in significantly quicker lap times.

VDL Fuel Systems has done extensive dyno testing to establish the proper air/fuel circuitry and to produce a flat curve that results in maximum torque and horsepower. Most racing carburetors can be jetted to produce big torque numbers or big top end horsepower numbers, but there is always a trade off between the two. VDL Fuel Systems’ CNC carburetors have a balanced network of metering systems that produce a superior performance curve from start to finish.

Assembly is done to tolerances unobtainable in high volume production. Boosters are installed to within .001’’ on height, twist, and pitch. The base plate is matched to the main body. All gaskets are properly matched to the main body to prevent overhang. And finally, the throttle plates are adjusted for optimum position angle on the flow bench.

Track testing has given VDL Fuel Systems an extensive database for producing optimum throttle response and drivability in specific applications. VDL Fuel Systems produces a custom built; fully optimized CNC carburetor built to your specifications and engine application – not just another “out of the box” carburetor. You will notice the difference!

- Custom built to customer’s engine specs

- All aluminum components with billet base plate and blocks

- CNC main body to maximize air flow

- Air/fuel circuitry calibrated

- Idle circuit calibrated

- Accelerator pump circuit tailored to application

- Thinned nickel throttle shafts with stainless buttonhead screws

- Base plate matched to main body

- Boosters calibrated, sized, and precision installed

- All parts vibratory polished for enhanced airflow

Applications:

- 1.450 x 1.687 for 600-700 hp range $1450

- 1.450 x 1.750 for 650-800 hp range $1450

- 1.500 x 1.750 for 750-900 hp range $1450

- 1.590 x 1.750 for 800-950 hp range $1450

- 1.600 x 1.750 for 850-950 hp range $1450

TUNING TIPS FOR YOUR VDL CNC CARBURETOR

Float Level – The fuel level in the bowls should be set at the bottom of the sight hole so that you have to jostle the car to get the fuel to come out the sight hole when running. We set the floats in the shop to a particular setting; but fuel pressure dictates fuel level. Therefore you must set this when you first install the carburetor. Finally, after setting the floats, always give the carburetor time to burn off enough fuel to reopen the needle/seat so that your new setting is really what you are seeing. Many times people lower the floats too much because they haven’t waited a sufficient amount of time for the fuel to burn off and the new setting to take.

Throttle Blade Adjustment – The throttle blades should be set at an rpm that is as low as possible to keep the transfer slots covered at closed throttle position. Keep the primary and secondary throttle blades adjusted equally. If you should lose your setting just back it completely off, put 1 round in the primary and 1 round in the secondary and start there.

Idle Mixture Screws – Always adjust the 4 idle mixture screws evenly. The settings on all 4 should be the same. Our original setting is 1 1/2 turns out. If for some reason your engine absolutely needs a different setting on one side or corner you can just about bet something is wrong with the engine causing it to have a different signal/vacuum on that side/corner.

Fuel Pressure – 6.5 to 7.5 pounds. You should absolutely know what your fuel pressure is! Many racers have no clue what their fuel pressure is, and they chase engine problems for weeks when a simple fuel pressure gauge would have indicated the problem straight away.

Vent Tube Clearance – You must have at least ¾” clearance above the vent tubes. It is ok to lower the vent tubes if absolutely necessary, but you will begin to run the risk of fuel spilling over in the turns if you are not careful.

Pump Circuit Tuning – Because of the differences in track conditions and driving styles you may need to adjust the pump circuit, i.e. pump cam/pump arm, to correct “off corner” stumbling issues. If an engine stumbles two or three times after the driver steps into the throttle this usually indicates too much fuel and can be corrected by adjusting slack in the pump arm or installing a smaller pump cam. If an engine has a “dead hesitation” and then picks right up and goes, this usually indicates not enough fuel on the pump circuit. First check that the pump arm has no slack in the adjustment then proceed to increase pump shot with either a larger pump cam or a larger pump nozzle.